God and Nature Summer 2020

By Paul Arveson

We returned to Maryland from a mission trip to Egypt in mid-March 2020, as Covid-19 was beginning its spread around the world. By the end of the month, fear of the pandemic had reached its highest level—the stock market had crashed, and grocery stores were cleared of disinfectants and paper supplies.

I wanted to do something practical to serve our community during this crisis. Our local Rotary club had rapidly organized a food collection and distribution service for the suburban DC area. I could have joined them on this or many other such activities that were starting up. But I wanted to figure out what I could do that would utilize my technical skills—I wanted to help with something that not everyone could do. Recognizing the vast demand for PPE, I decided to join a small group of local "makers" to fabricate face shields, masks, and the like using 3D-printing technology.

We returned to Maryland from a mission trip to Egypt in mid-March 2020, as Covid-19 was beginning its spread around the world. By the end of the month, fear of the pandemic had reached its highest level—the stock market had crashed, and grocery stores were cleared of disinfectants and paper supplies.

I wanted to do something practical to serve our community during this crisis. Our local Rotary club had rapidly organized a food collection and distribution service for the suburban DC area. I could have joined them on this or many other such activities that were starting up. But I wanted to figure out what I could do that would utilize my technical skills—I wanted to help with something that not everyone could do. Recognizing the vast demand for PPE, I decided to join a small group of local "makers" to fabricate face shields, masks, and the like using 3D-printing technology.

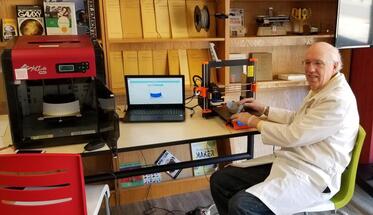

I had earlier taken a short course in 3D printing, but I did not have a machine. A local computer store was selling one for $210, so in early April I bought one and I brought it to our local "maker space,” Rockville Science Center. Working with the manager of the center, Abdel Elhamdani, we gathered several 3D printers and proceeded to fabricate a variety of objects, including face masks, face shields, and little straps that support surgical masks behind the head. Abdel helped me to assemble my printer and get it prepared for printing. Working together, we have produced hundreds of copies of various designs of PPE. (The NIH has now set up a 3D Print Exchange website to collect codes that can be used to print these designs.) We distributed our products to nearby grocers and carry-out shops, as well as to local distribution points that the county had set up.

Recently, with the increased supply of PPE available for health care workers, they are no longer accepting products made by amateurs. However, I found one remaining product that was still in high demand. My daughter Genevieve is an RN on the labor and delivery floor of a nearby hospital, and she told me the nurses are in need of surgical mask straps, which take stress off their ears from wearing masks all day. So we printed packs of these little devices, and I drove over to the hospital entrance and handed them to her for distribution. You should have seen the smile on her face when we gave her a pack of a hundred of these.

As the "makers" advised me, 3D printing is a hobby, not a professional operation. It is difficult to get the printer settings right, and there are many printing failures. After this episode is over, I plan to donate my printer to creative young students in Rockville Science Center.

Paul Arveson is a retired physicist and computer system engineer. He served as a leader in the Washington DC ASA Chapter for many years. He lives with his wife Kathy and has two children. He is an elder in the National Presbyterian Church and serves on the board of the Washington Academy of Sciences.

Recently, with the increased supply of PPE available for health care workers, they are no longer accepting products made by amateurs. However, I found one remaining product that was still in high demand. My daughter Genevieve is an RN on the labor and delivery floor of a nearby hospital, and she told me the nurses are in need of surgical mask straps, which take stress off their ears from wearing masks all day. So we printed packs of these little devices, and I drove over to the hospital entrance and handed them to her for distribution. You should have seen the smile on her face when we gave her a pack of a hundred of these.

As the "makers" advised me, 3D printing is a hobby, not a professional operation. It is difficult to get the printer settings right, and there are many printing failures. After this episode is over, I plan to donate my printer to creative young students in Rockville Science Center.

Paul Arveson is a retired physicist and computer system engineer. He served as a leader in the Washington DC ASA Chapter for many years. He lives with his wife Kathy and has two children. He is an elder in the National Presbyterian Church and serves on the board of the Washington Academy of Sciences.